SPINDASYN motors are hollow-shaft motors and enable direct mounting of a wide range of ball or planetary roller screws. They contain all the components required for linear actuators, such as a servo motor, DIN mounting for ball screw, optional holding brake, and position encoder.

The motor bearings are designed for high axial forces up to 570 kN. SPINDASYN motors are very dynamic and feature high rigidity and zero backlash. SPINDASYN motors are available in convection-cooled and liquid-cooled versions.

The SPINDASYN SKT hollow shaft motors are compact mechatronic functional units consisting of a powerful servo motor with integrated thrust bearing and multi-turn absolute encoder. They have a modular design.

The SKT linear servo motor combines with a screw and nut system to form a ready-to-use linear drive. SPINDASYN hollow shaft motors are the more efficient alternative to pneumatic or hydraulic drives when high loads must be moved at different speeds, e.g., in (electric) presses.

功能和應用程序

Anti-twist protection

In linear movements, the motor torque is applied to the screw in the opposite direction. This torque has to be braced by a linear guidance.

Companion structure

Radial loads or overturning torques reduce the life of the screw-nut systems. With the companion structure, make sure that the motor and screw-nut system are flush with each other and that no radial forces are present.

Screw-nut system

SKT motors are suitable for screw-nut systems such as roller or ball screws. As a rule of thumb, roller screws can support larger forces with smaller diameters while ball screws offer better dynamic performance and are more cost-effective.

產品優勢

Flexibility via modular concept

The modular design of SPINDASYN linear drives with respect to performance, screw diameter and axial force allows them to be specifically adapted to various applications. There is the choice from models with hollow through-shafts or blind hollow shafts, so that there is the option of limiting the strokes or not.

Energy efficiency

Compared to hydraulic systems and linear direct drives, SPINDASYN offers significantly higher efficiencies. Thus the customer achieves a better overall energy efficiency.

Extremely compact design

Since SPINDASYN includes an integrated screw, an entire linear drive with minimal dimensions can be designed. All of the functional elements such as the servo motor, bearing, DIN fitting for screw nuts, holding brake and encoder system are concentrated together as a compact unit within a single enclosure.

High stiffness

The integrated bearing eliminates the need for shaft couplings and significantly reduces the number of bearing points required. With the stiffness enclosure and the amply dimensioned power-train components, the entire system provides extreme stiffness.

High dynamic performance

Since the design is extremely compact, the moment of inertia is also very low. The servo motor offers high power and acceleration ratings as well as high overload capacity. Of special note, the torsionally stiffness connection to the screw nut allows very dynamic controller settings to be used.

Reduced design complexity

The ready-to-install unit consists of a servo motor, heavy duty bearing and multiturn absolute encoder and can be connected directly to a screw nut.

IP54 protection rating

With IP54 protection rating, these motors are also suitable for harsh environments.

Installation at any location

Fitted with sealed bearings, SPINDASYN units can be installed in any location. According to customer application, the bearings can also be re-lubricated.

Maintenance-free operation

Since SPINDASYN uses high-torque motors with sealed enclosures, they are practically maintenance-free and offer high availability. The integrated temperature sensors protect the motors against thermal overloading. Depending on the lifetime lubricated angular contact ball bearings and tapered roller bearings may have to be re-lubricated.

Heavy duty applications and high speeds

SPINDASYN hollow shaft motors are an efficient alternative to existing hydraulic solutions or linear drives in applications where high loads have to be moved at various different speeds.

Highest power density through liquid cooling (optional)

Liquid-cooled motors are compact in design and offer higher dynamic performance through less moving mass. Since the motors weigh less and are smaller in size, they are also easier to install.

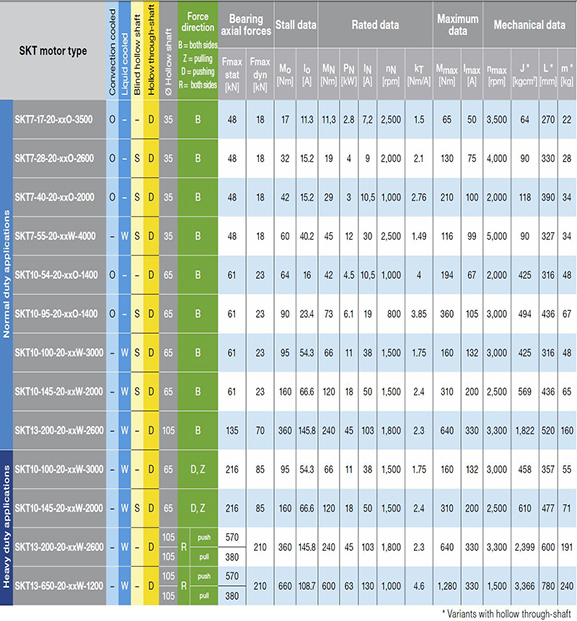

技術數據

自定義選項

|

Bearing side of motor

|

Active component of motor

|

Motor end

|

|

|

|

Normal duty bearing

- Lubricated-for-life, normal

duty bearing with

continuous lubrication

depending on application

- Good acceleration

characteristics

- Support of high axial loads

- For pushing and pulling

forces

- Seals on both sides of the

bearing offer good

protection against dirt

- High stiffness and low

friction

- For dynamic applications

for sizes SKT7, SKT10, and SKT13

|

Convection-cooled

- Various overall lengths for

each size

- Highly dynamic

- High maximum torque

- Smooth surface

|

Hollow through-shaft

- No limits in screw stroke

- Compact overall lengths

- Multiturn absolute encoder

- Optional hollow shaft brake

|

|

|

|

Heavy duty bearing

- For highest forces in sizes

SKT10 and SKT13

- Lubricated-for-life heavy

duty bearing with

continuous lubrication

depending on application

- Support of highest axial

loads

- Especially suited for heavy

duty screws

- Static forces of up to 570 kN

- Dynamic forces of up to

210 kN

- High stiffness and low

friction

|

Liquid-cooled

- Various overall lengths for

each size

- Highly dynamic

- High maximum torque

- Smooth surface at the end

- Increase in continuous

torque for shorter cycle

times

- Cooling circuit made of

stainless steel to protect

against corrosion

|

Blind hollow shaft

- Closed end of motor

- Bleeding of trapped air via

front end bell

- Multiturn absolute encoder

- Optional holding brake

|